Kevin

Installer

Kevin

Installer

About Kevin:

Bio is coming soon!

Customers love working with Kevin

See AllJobs Completed by Kevin

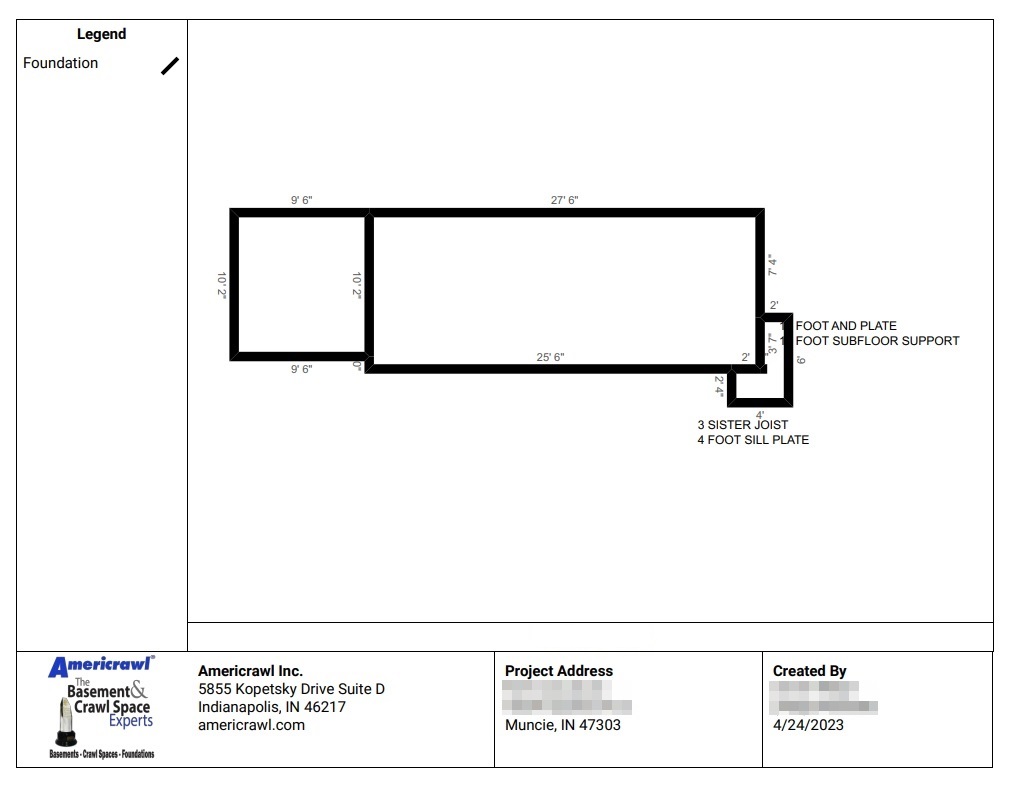

See AllMuncie, IN

May 4, 2023

Anderson, IN

April 19, 2023

Anderson, IN

April 6, 2023

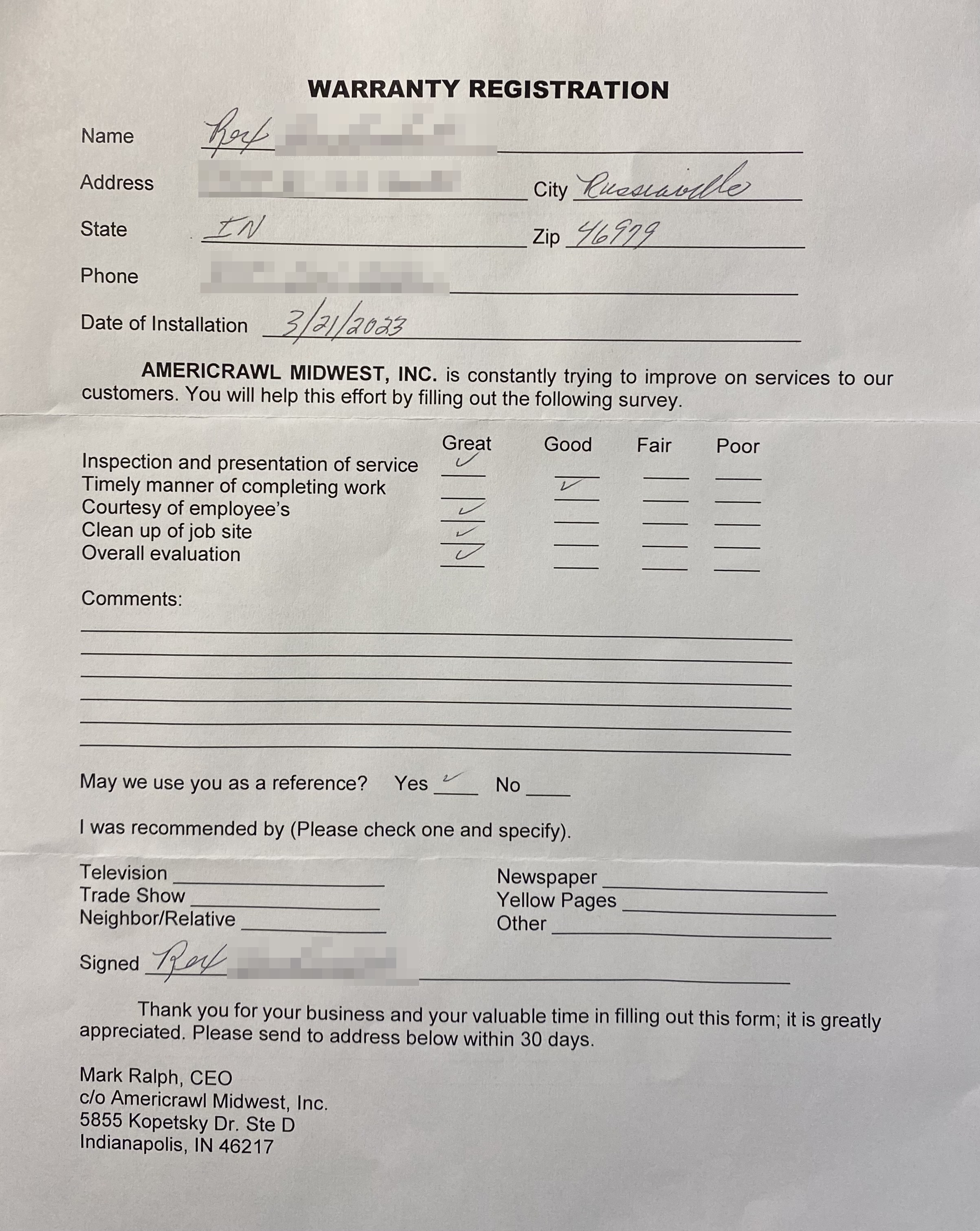

Russiaville, IN

March 21, 2023

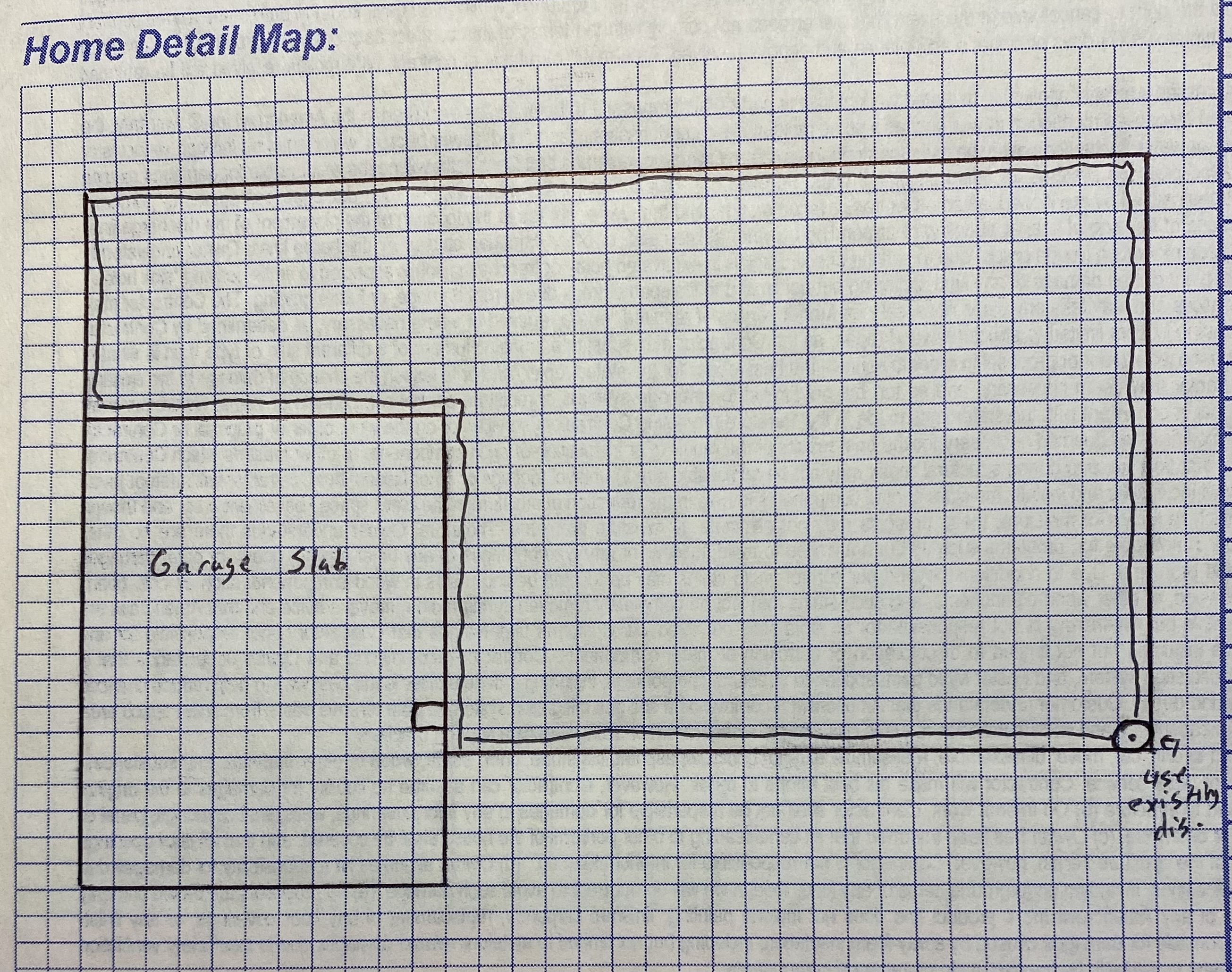

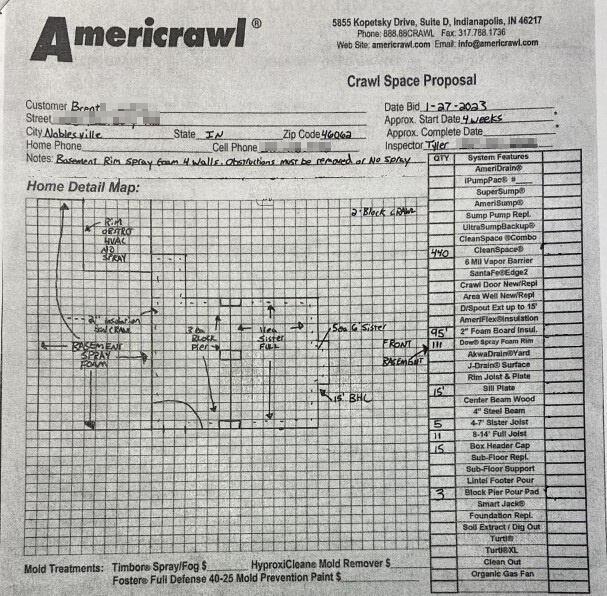

Noblesville, IN

March 20, 2023

Indianapolis, IN

January 3, 2023

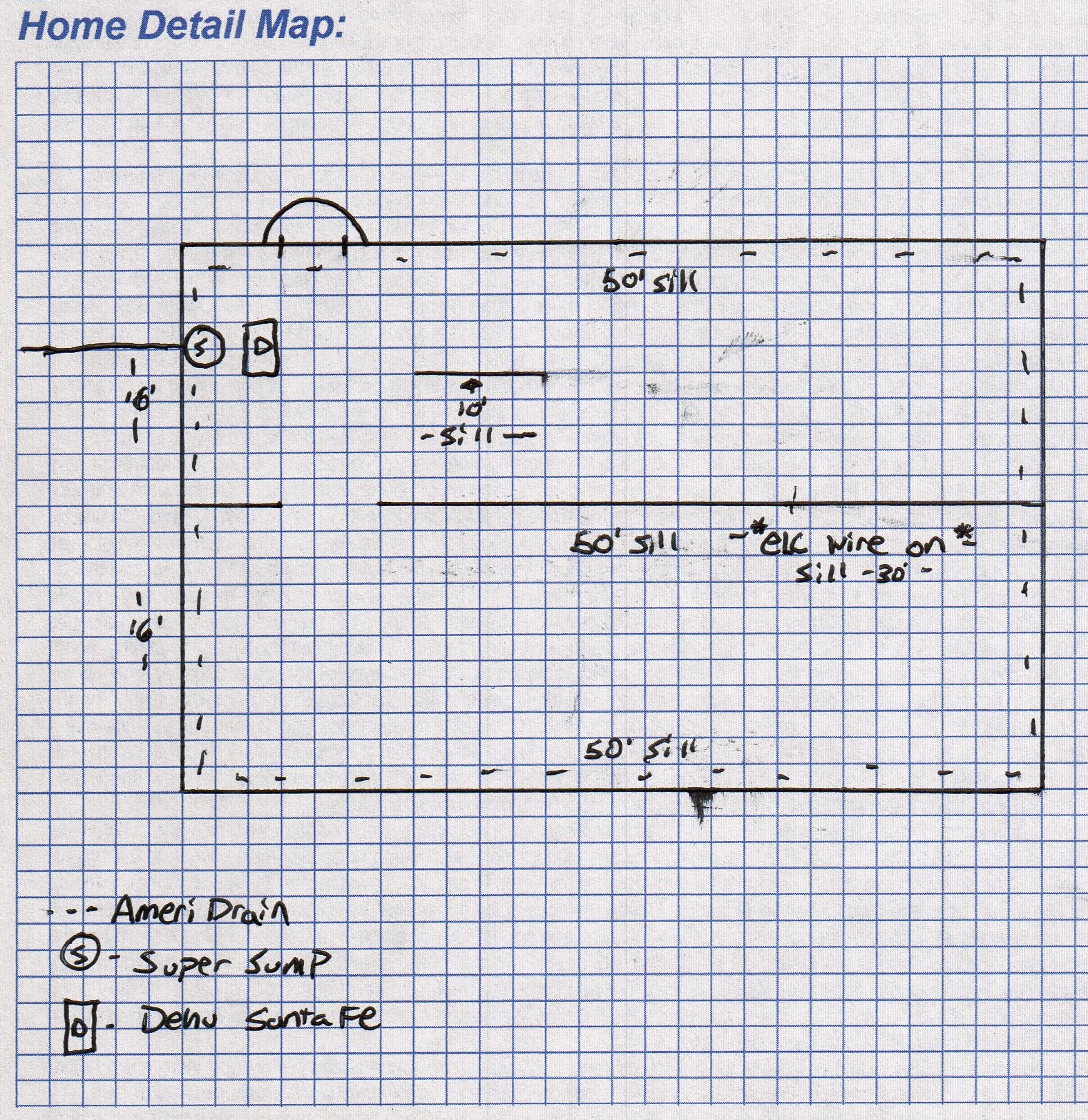

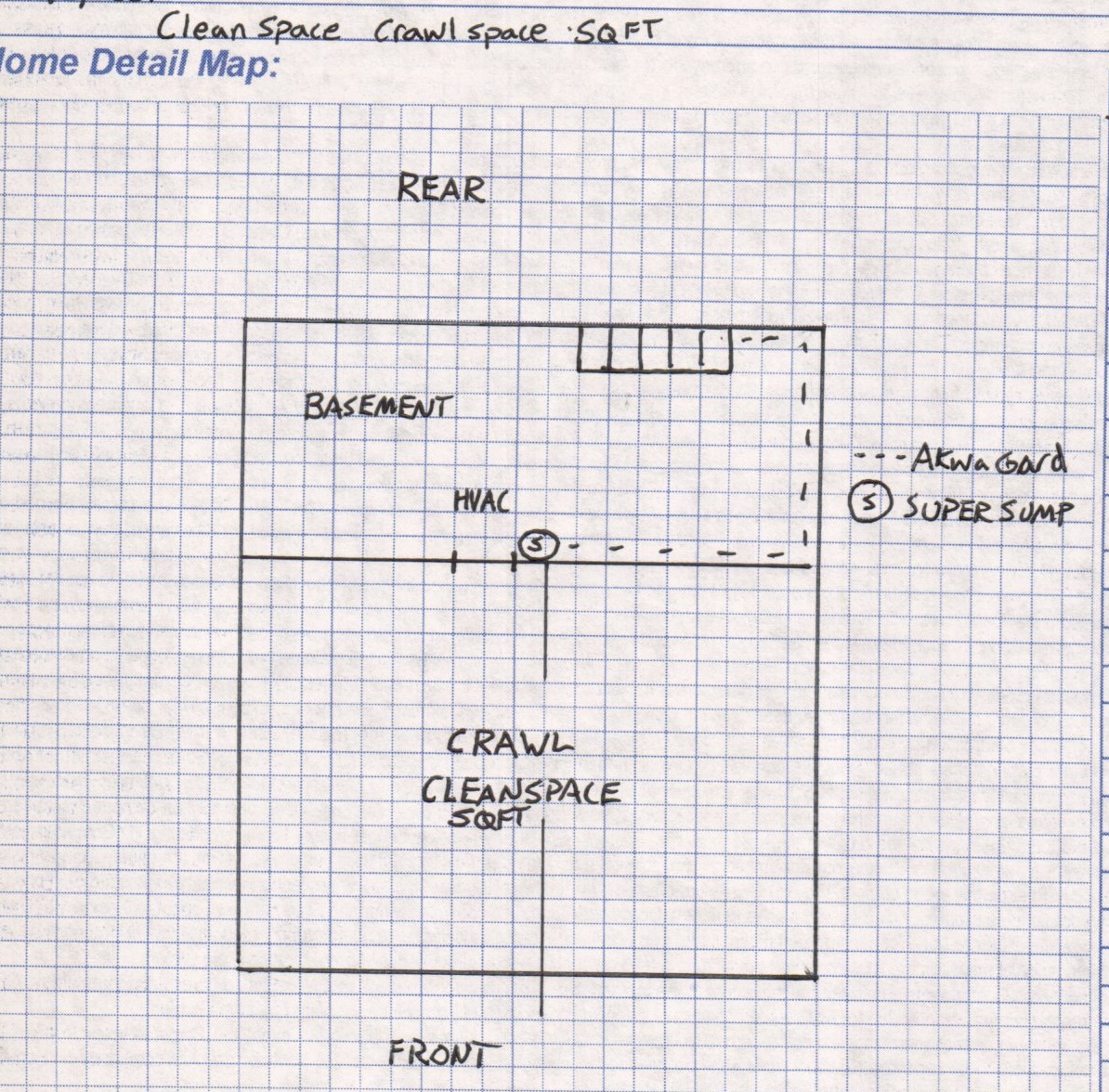

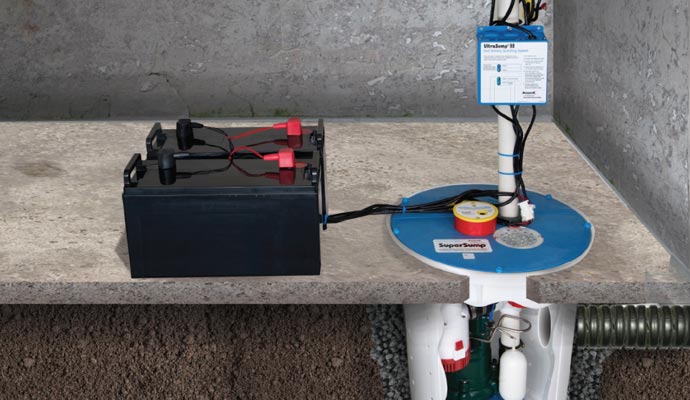

Americrawl provided a complete crawlspace repair solution to address a wet and damaged crawlspace. The project included the installation of 164 linear feet of AmeriDrain Crawlspace Drainage System and a SuperSump sump pump system to effectively manage excess moisture and prevent future water intrusion. A durable 1,600 sq. ft. CleanSpace vapor barrier was installed to encapsulate the crawlspace and protect against humidity and mold growth. To further improve air quality and control moisture, a high-performance dehumidifier was added. Structural repairs included 160 linear feet of sill plate replacement, 76 full floor joists, and 100 linear feet of box header cap, restoring the home’s foundation integrity. Additionally, an area well replacement enhanced drainage and access. This comprehensive Americrawl system ensures a dry, stable, and energy-efficient crawlspace for years to come.

Indianapolis , IN

August 8, 2022

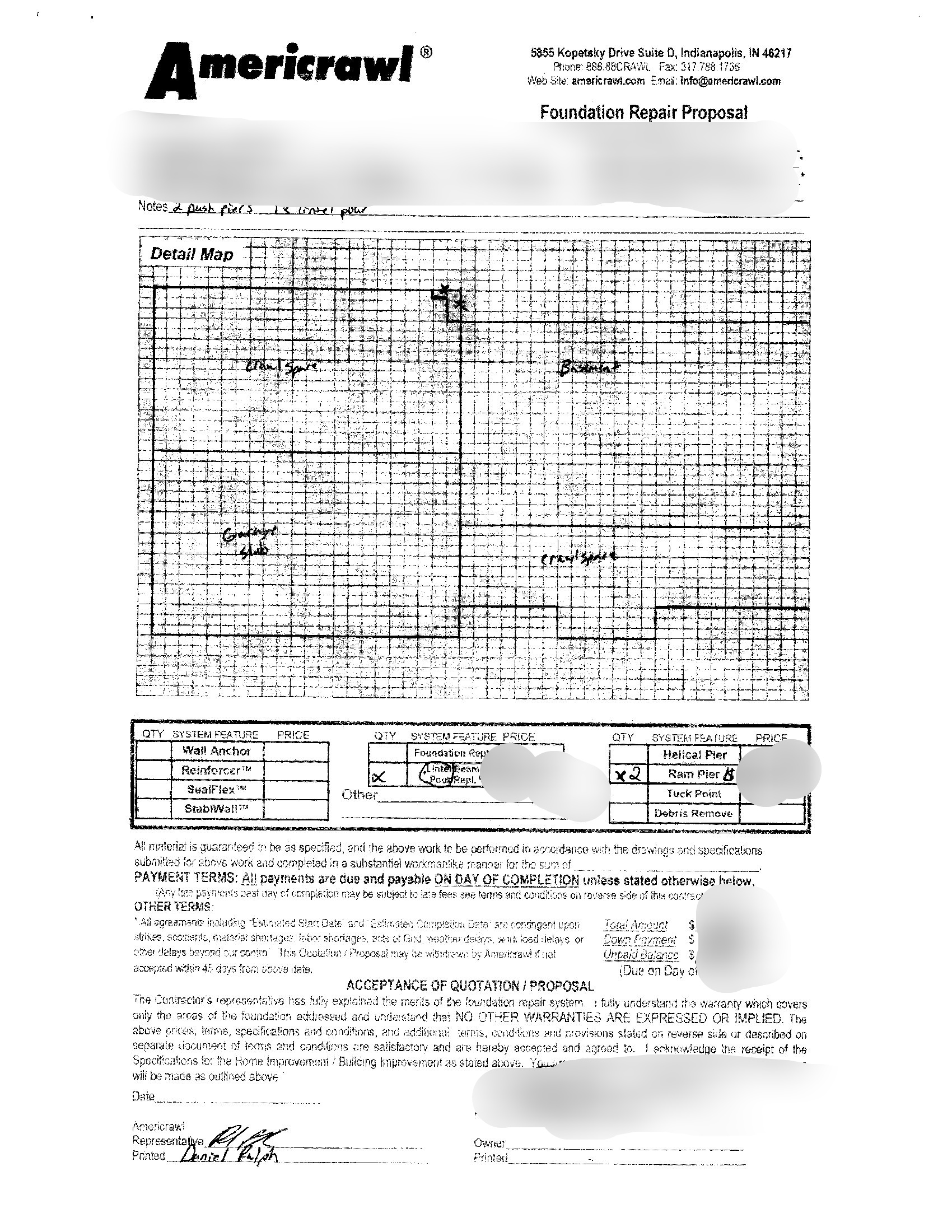

To provide a permanent solution, Americrawl installed 4 of Dyna® Push Piers a foundation repair method that transfers the weight of the home from unstable soils to deep, load-bearing strata far below the surface. The installation process began by excavating small sections along the foundation where the piers would be installed. Each steel pier was hydraulically driven into the ground until reaching the proper depth and load-bearing capacity. Heavy-duty brackets were then attached to the foundation footing, allowing the home’s weight to be securely supported by the piers. In some cases, lifting was performed to bring the foundation closer to its original position, helping to close cracks and restore the homes foundation.

Kokomo, IN

June 13, 2022

For this project, we began by performing a complete clean-out of the crawlspace, removing any debris, old insulation, and materials that could contribute to moisture issues or mold growth. After the space was fully cleaned, we installed 550 square feet of our premium CleanSpace Encapsulation System. This heavy-duty vapor barrier was carefully sealed to the crawlspace floor and walls, creating a continuous moisture barrier to prevent water intrusion, reduce humidity levels, and protect the structural integrity of the home.

Sharpsville , IN

January 28, 2022

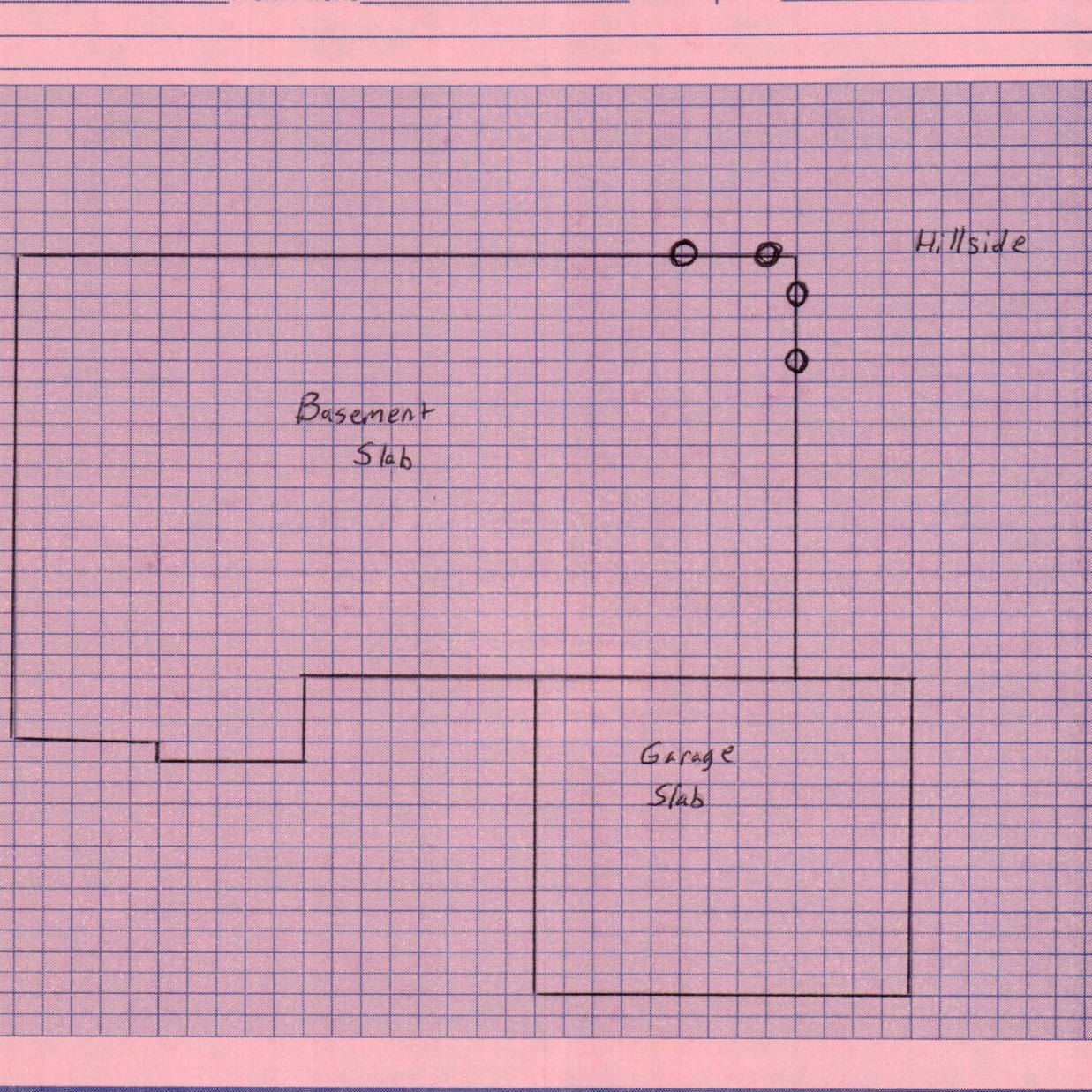

The project included comprehensive structural and moisture-management improvements within the crawlspace to stabilize the foundation and protect the home long term. Work performed consisted of installing two Dyna Pier push piers at the corner of the crawlspace to permanently stabilize and support the settling foundation. A poured concrete lintel was constructed to restore proper load distribution and reinforce the affected opening. Additional structural repairs included removal and replacement of damaged rim and sill plates, center beam supports, and full-length floor joists, with new poured concrete pads installed to provide proper bearing for the center beam. To address water intrusion and moisture control, an interior drainage system was installed along the crawlspace perimeter and routed to AmeriSump pump systems, followed by installation of a reinforced vapor barrier to encapsulate the crawlspace. Together, these repairs improve structural integrity, control groundwater and humidity, and help ensure long-term durability of the home’s foundation and crawlspace environment.

Noblesville , IN

December 10, 2021

The scope of work includes the installation of one durable steel crawlspace access door to provide secure and long-lasting entry to the crawlspace area. In addition, a 30-foot steel I-beam is installed beneath the home to provide substantial structural support. The I-beam is carefully set in place and supported by eight SmartJacks, which are properly spaced and anchored to ensure even load distribution. These SmartJacks are adjusted as needed to stabilize and reinforce the existing floor joist system, reducing sagging and deflection while restoring proper support to the floor structure. This system enhances the overall structural integrity of the home and provides a reliable, long-term solution for floor stabilization.

Edinburgh, IN

November 22, 2021

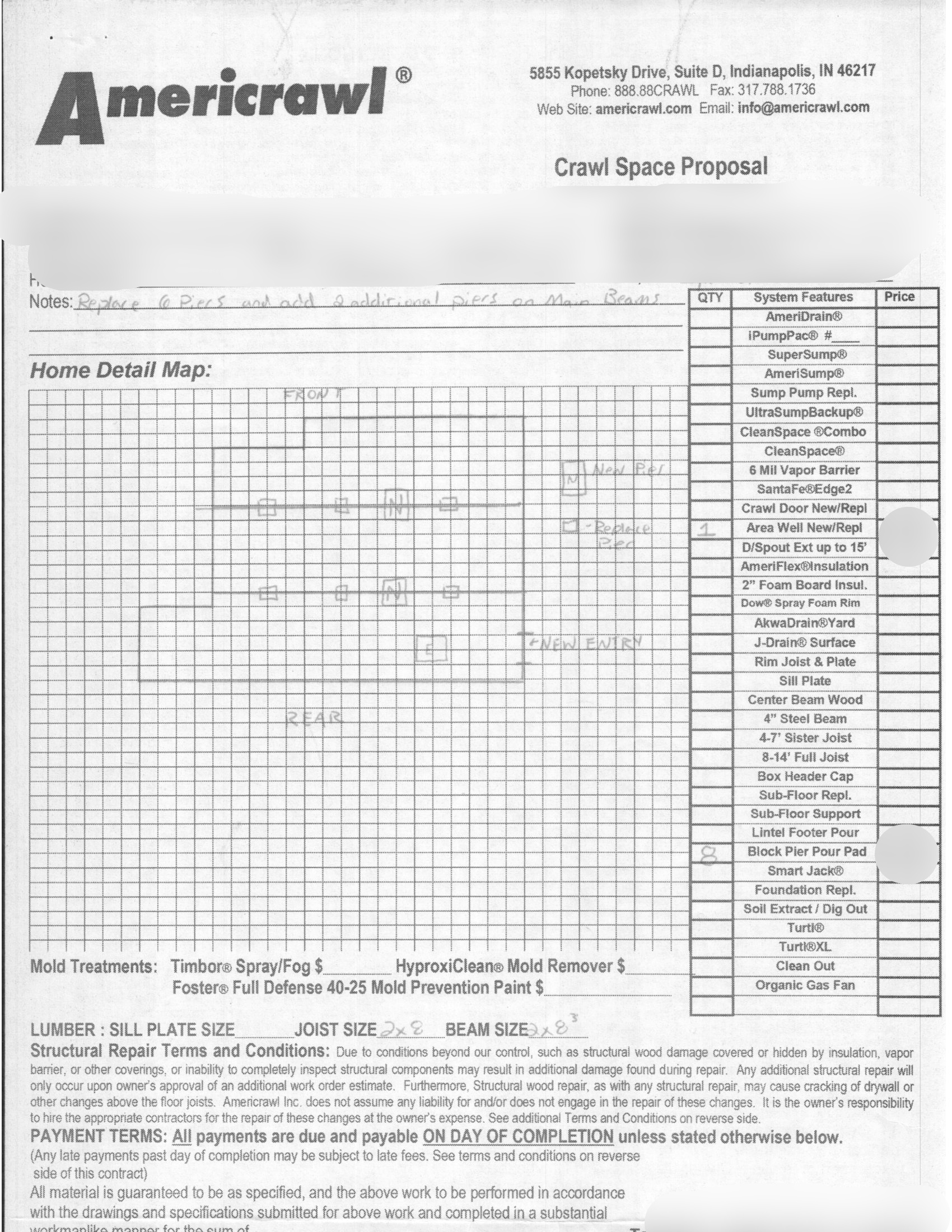

The scope of work includes the installation of one steel crawlspace access door to provide secure and long-lasting entry to the crawlspace. In addition, eight poured concrete pads are installed beneath the center beam of the home to create stable and properly engineered bearing points. An 18-foot section of the center beam is then replaced and set on the new concrete pads, restoring proper structural support to the floor system. This work corrects existing deficiencies, improves load distribution, and enhances the overall structural stability and integrity of the home.

Marion , In

July 15, 2021

For this project, our team installed 160 linear feet of the AmeriDrain Drainage System along the crawl space perimeter to direct groundwater away from the foundation. To ensure effective water removal, we added a SuperSump sump station, providing reliable pumping capacity during periods of heavy rain. The crawl space was also thoroughly cleaned out to remove debris and prepare the area for encapsulation. Once cleared, we installed 1,680 square feet of vapor barrier, sealing the ground to help control moisture, reduce humidity, and protect the home from mold and mildew concerns.

Indianapolis , IN

December 27, 2018

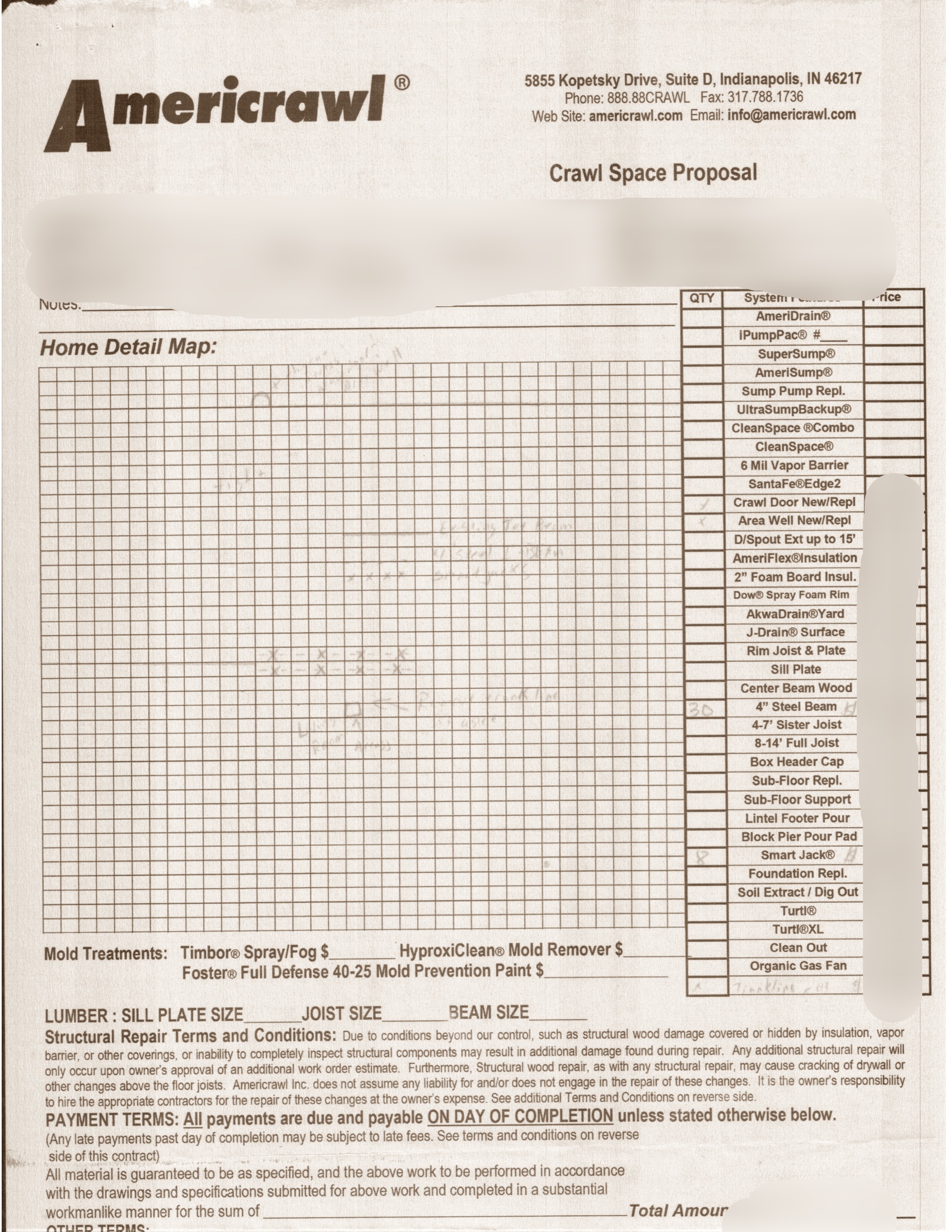

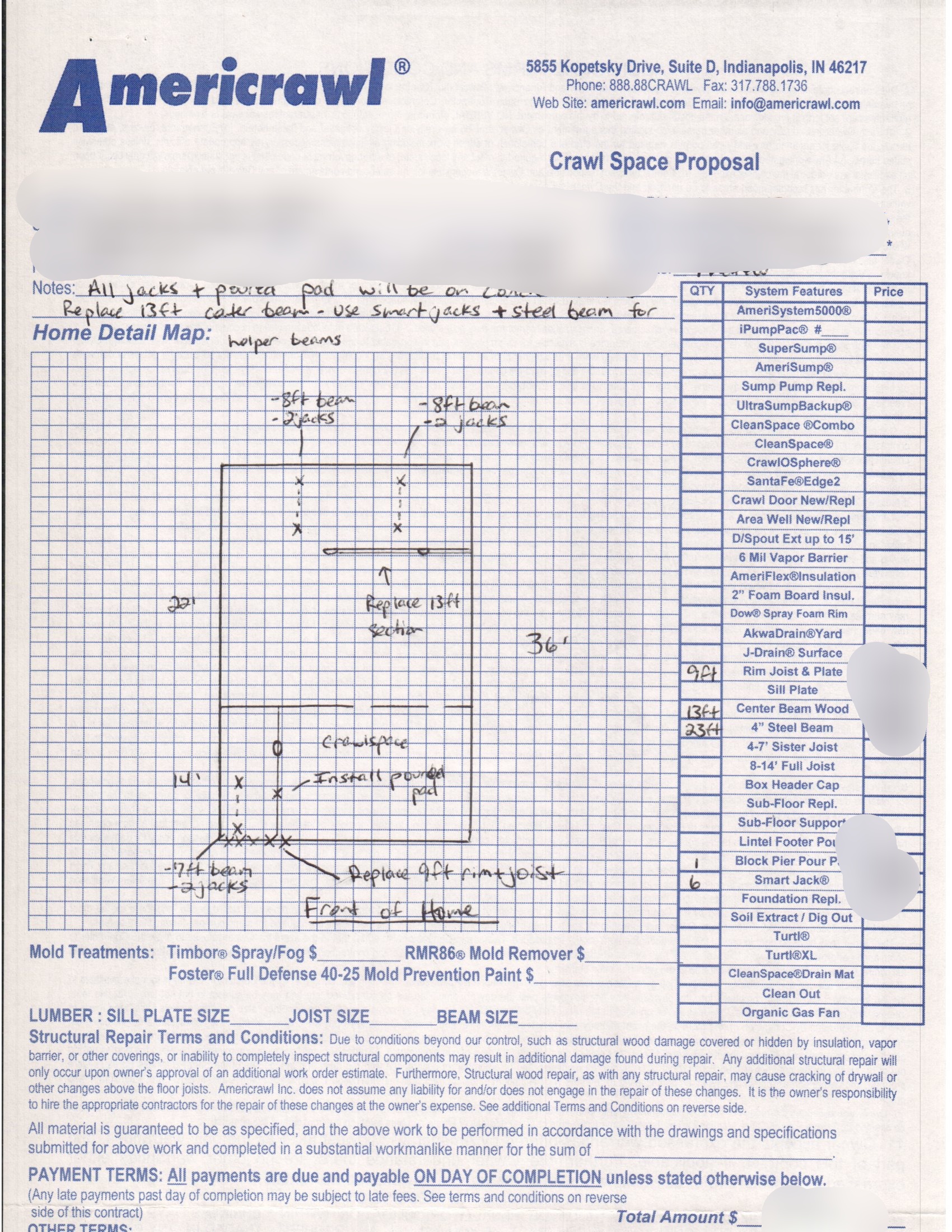

Our experienced crew installed a job that includes multiple structural repairs and reinforcements to restore proper support and stability to the home’s floor system. An 18-foot section of the center beam is replaced, along with an additional 13-foot center beam replacement, to address compromised or deteriorated structural members. Nine floor joists are sistered to reinforce weakened joists and improve load-bearing capacity. In addition, approximately 9 feet of rim joist and sill plate are repaired or replaced to restore structural integrity at the perimeter. A 23-foot steel I-beam is installed to provide enhanced floor support and is set on one poured concrete pad beneath the center beam to ensure a stable bearing surface. The I-beam is further supported by six SmartJacks, which are properly positioned and adjusted to evenly distribute loads and stabilize the floor system. Collectively, this work corrects structural deficiencies, reduces floor deflection, and provides long-term reinforcement to the home’s support structure.

Fort Wayne, In

May 6, 2016

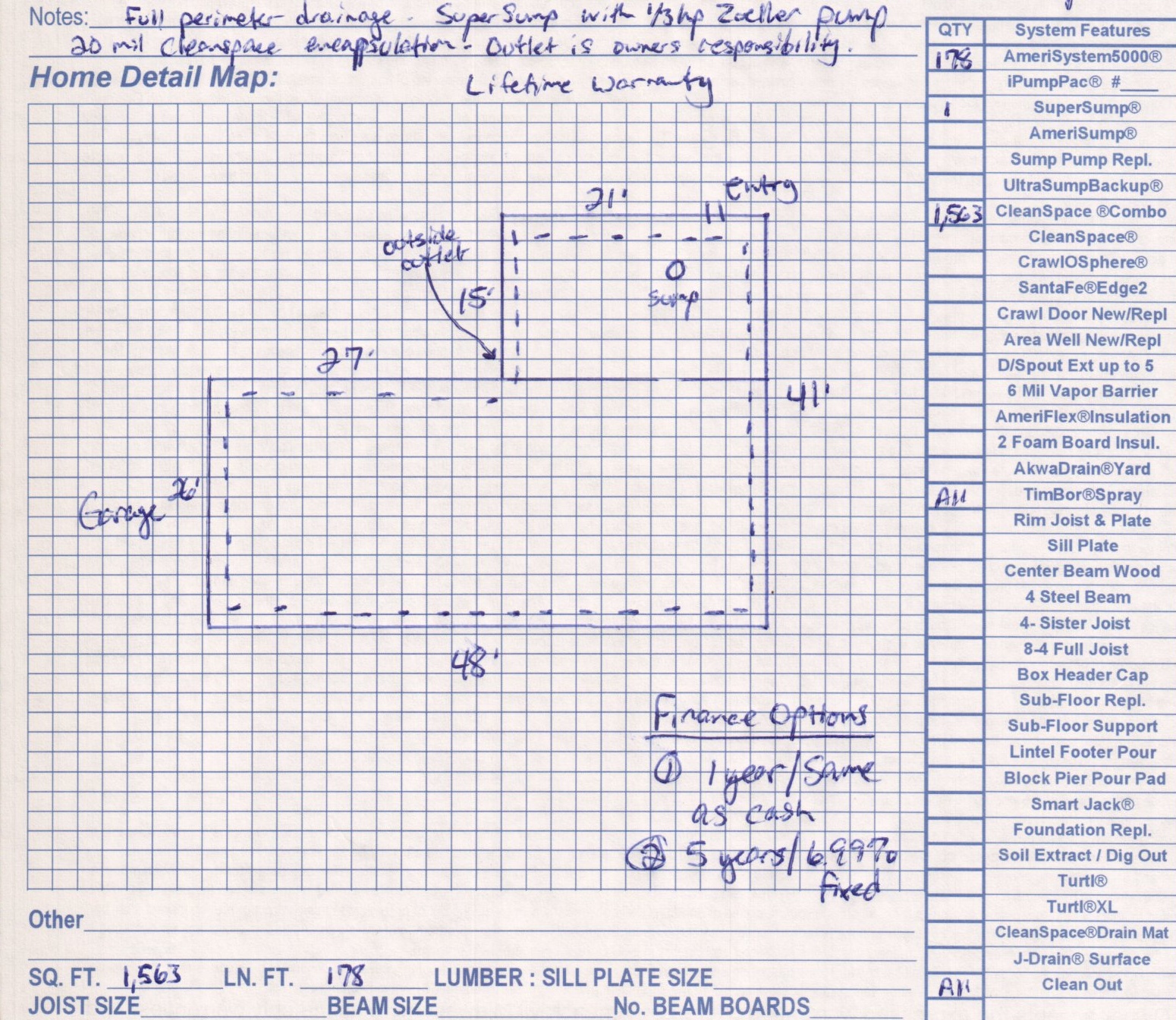

This project involved a complete cleanout of 1,563 square feet of crawl space, ensuring all debris and old materials were removed for a clean and stable foundation area. We installed 178 linear feet of the AmeriDrain drainage system to efficiently redirect water and prevent moisture accumulation. Additionally, a SuperSump sump pump system was installed to provide reliable water removal. The crawl space was then fully encapsulated with 1,563 square feet of CleanSpace vapor barrier, creating a strong moisture barrier and improving overall air quality. To further protect the structural wood components, 1,563 square feet of Timbor Spray treatment was applied to prevent mold, mildew, and insect damage.

Indianapolis , IN

December 5, 2014

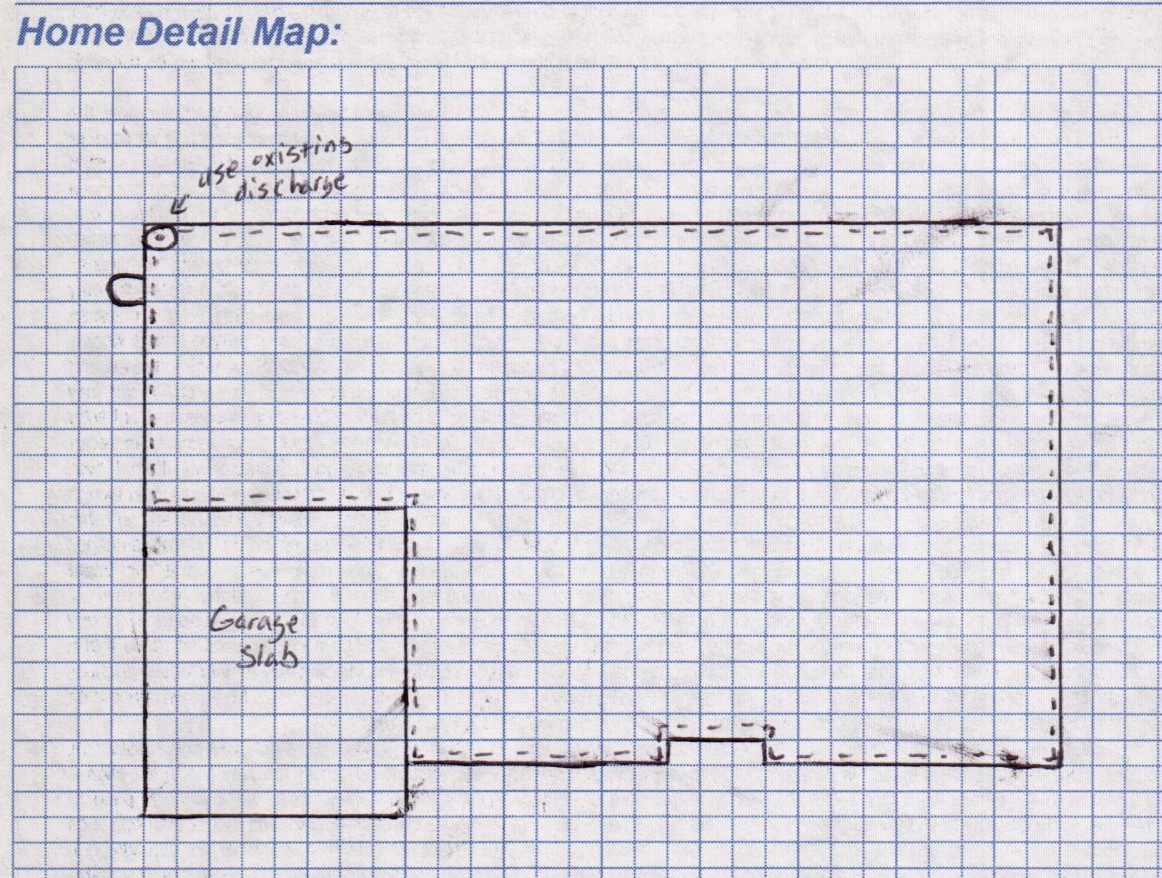

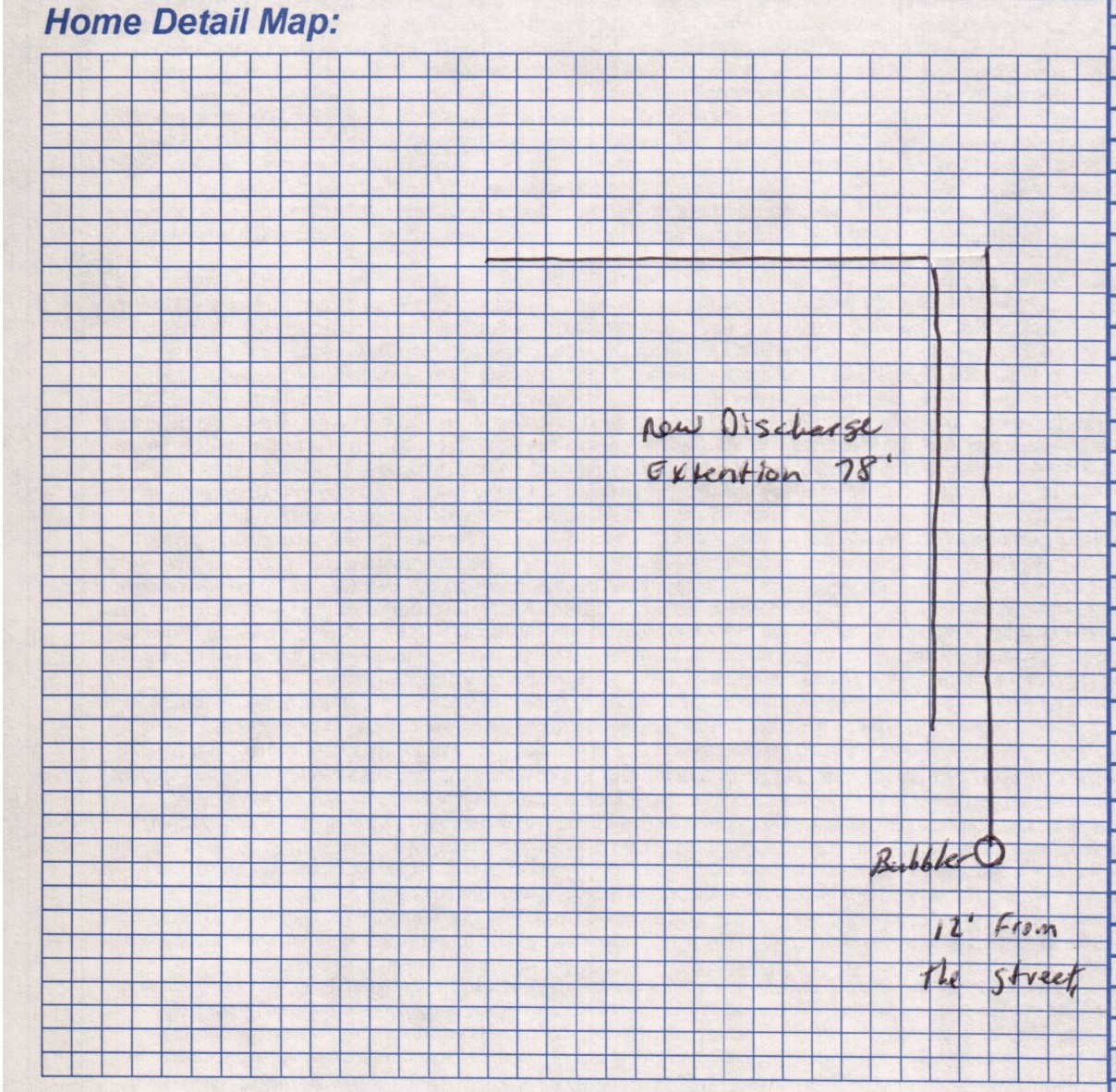

After a careful evaluation, our team recommended and installed a new 78-foot discharge line designed to carry pumped water far away from the home’s foundation to a safe drainage location. The project involved trenching a precise path for the line, ensuring proper slope for efficient water flow, and using durable piping materials built to withstand year-round weather conditions. The extended discharge route now ensures that water collected by the sump pump is directed well beyond the home’s backfill zone, eliminating the risk of recycled seepage and reducing hydrostatic pressure around the foundation. The line was securely connected to the sump pump outlet, with all joints sealed and tested for leak-free performance. The homeowner was extremely pleased with the results, noting improved pump efficiency, a cleaner discharge path, and the added peace of mind that their basement is better protected during storms. They also appreciated Americrawl’s attention to detail, tidy workmanship, and dedication to providing a long-term solution rather than a temporary fix.

Indianapolis, IN

December 13, 2010

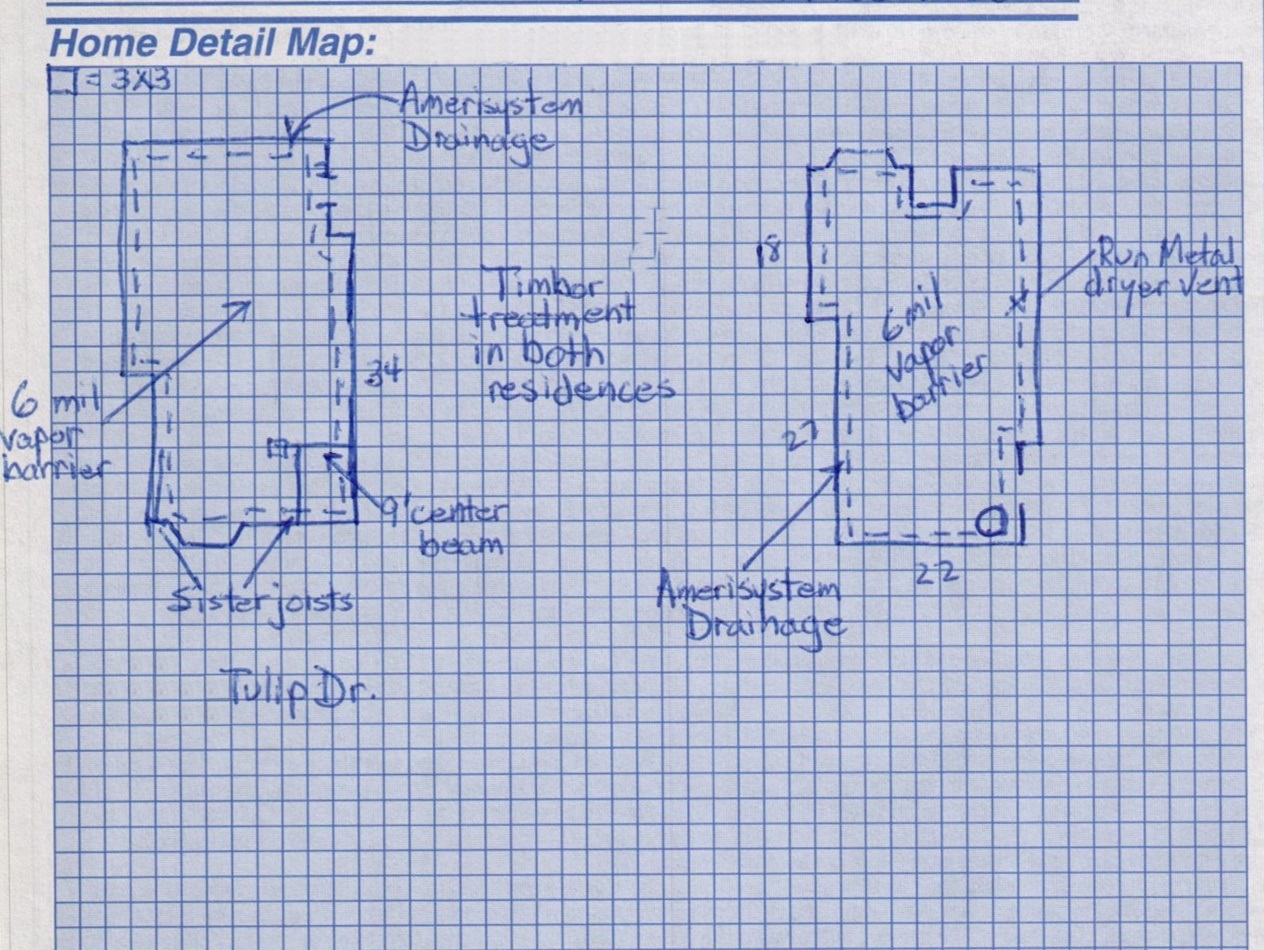

In the home’s crawlspace, a comprehensive repair was completed to address moisture and structural concerns. A crawlspace drainage system was installed to effectively collect and channel water away, preventing standing moisture and future flooding. A 6-mil vapor barrier was laid across the ground to seal out ground moisture and improve overall humidity control. Structural wood repairs were made to restore integrity and ensure stability. To address existing contamination, a mold treatment was applied to affected surfaces, eliminating growth and helping prevent recurrence, leaving the crawlspace clean, dry, and structurally sound.

Fishers , IN

August 21, 2008

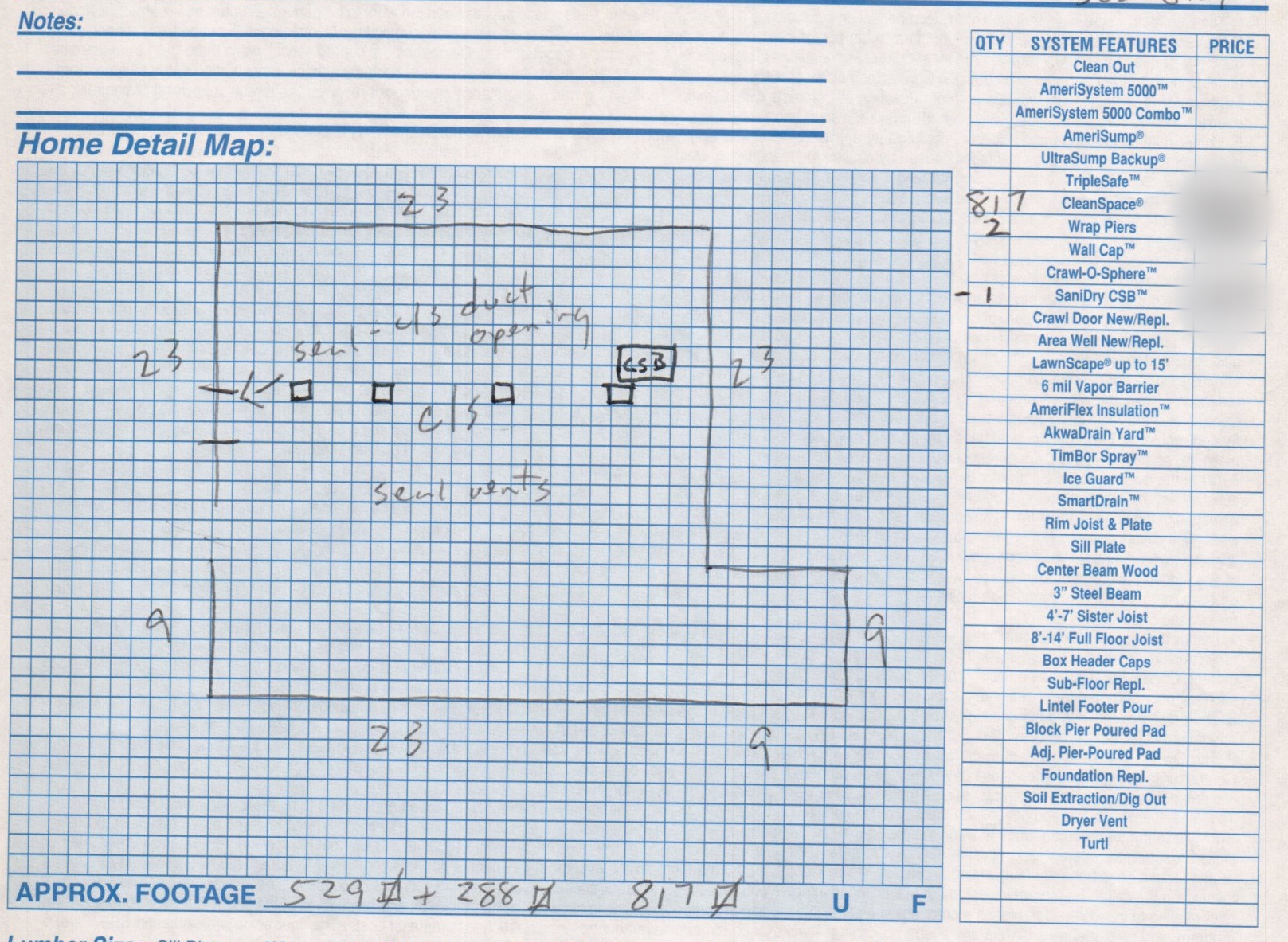

This project involved the installation of 817 square feet of CleanSpace encapsulation, providing a complete moisture barrier across the crawl space floor and walls. The encapsulation helps prevent ground moisture from entering the space, improving air quality and protecting the home’s structural components. To maintain optimal humidity levels, we also installed one Sedona dehumidifier, ensuring continuous moisture control and a healthier, drier crawl space environment.

Carmel, IN

August 14, 2008

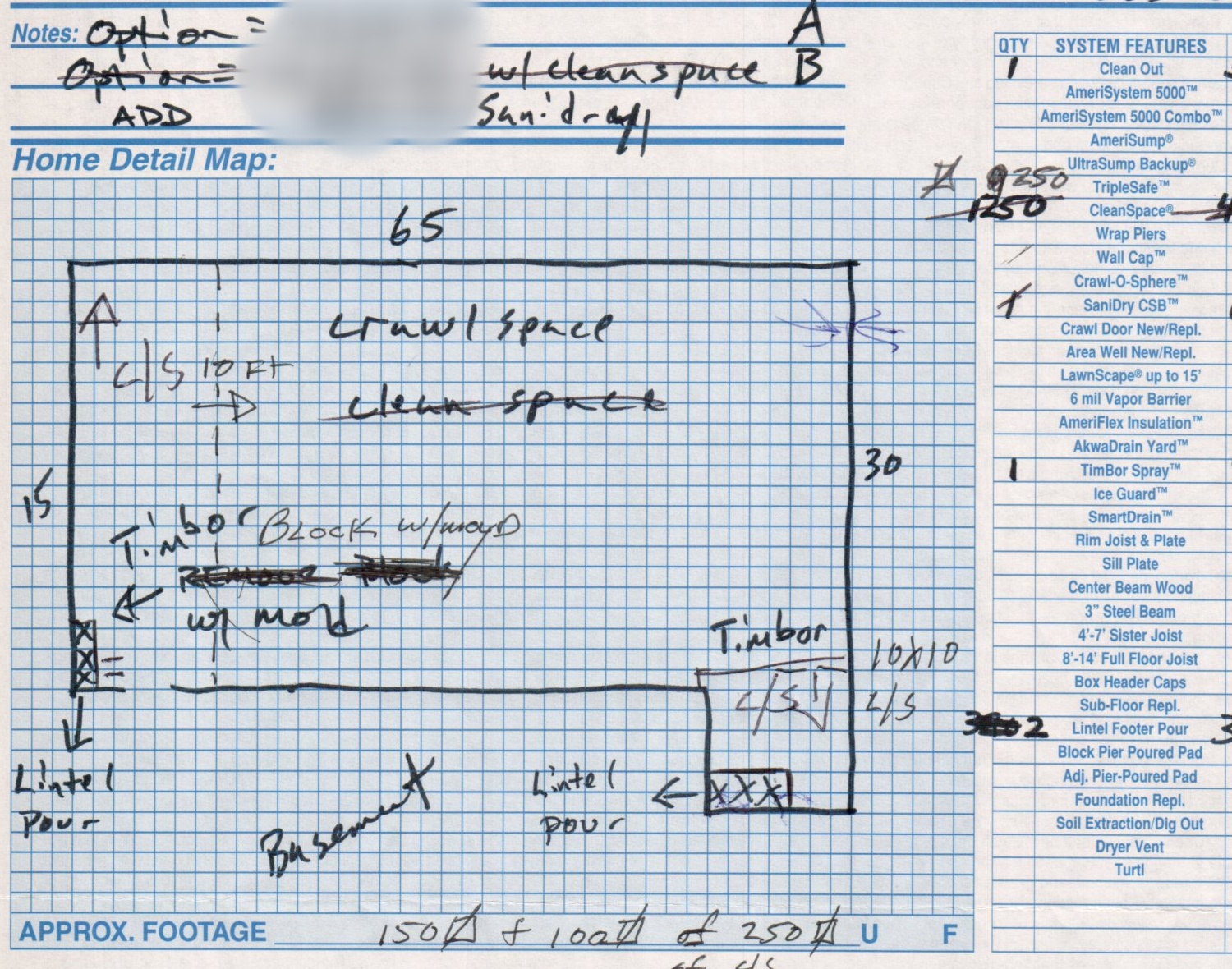

This crawlspace project included a 1,250 square foot CleanSpace encapsulation system following a full clean-out of the crawlspace to remove debris and prepare the area. To further protect the home, a Sedona dehumidifier was installed to maintain proper humidity levels. Structural improvements were addressed with two lintel pours, ensuring stability where footing support was needed. Finally, a Timbor spray treatment was applied throughout the space to protect the wooden components against mold and pests.

Layfayette, In

March 19, 2004

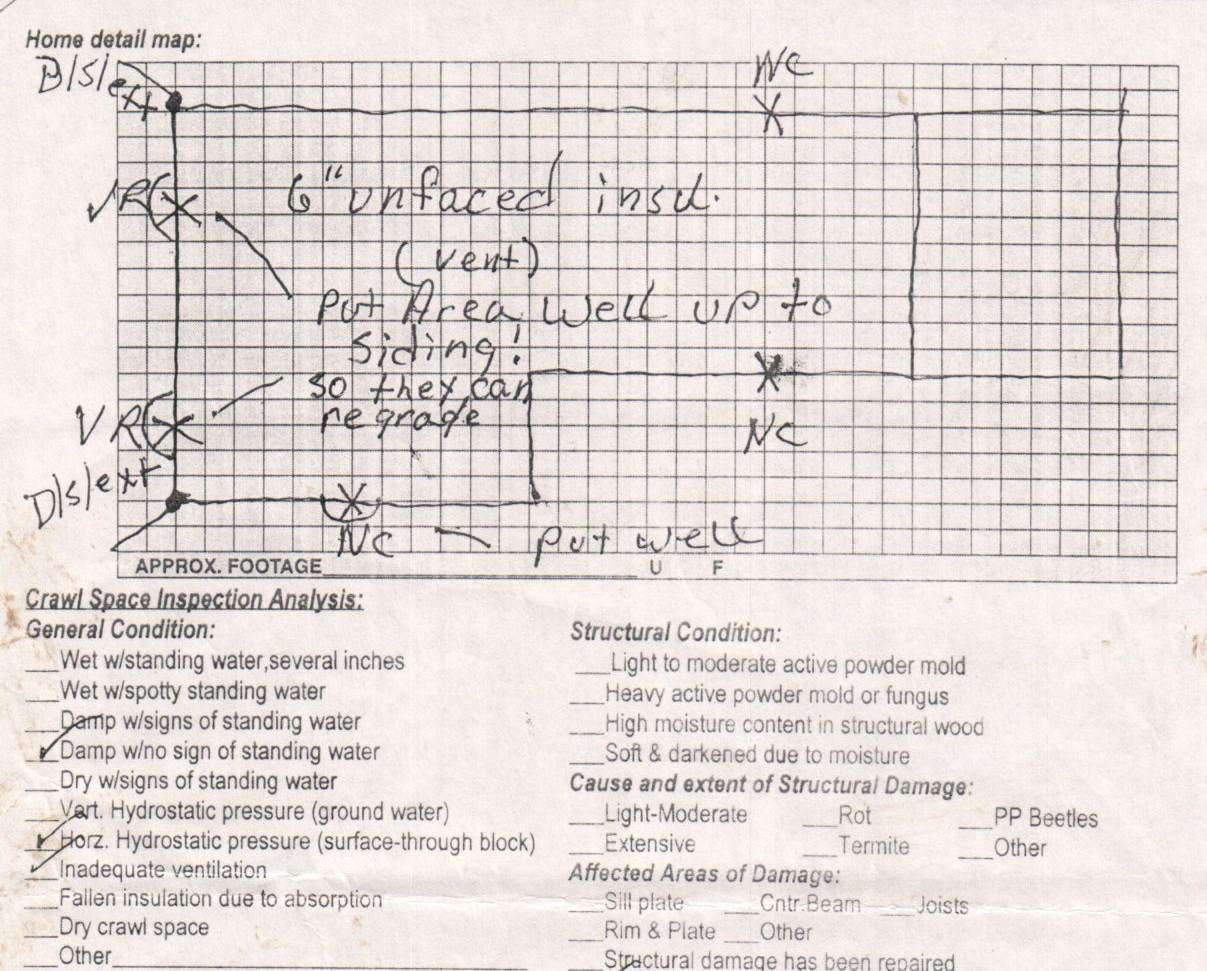

To improve moisture control, Americrawl installed a 6-mil polyethylene vapor barrier across the entire crawl space floor. The material was laid with overlapping seams, sealed, and secured to piers and edges to create an effective barrier against ground moisture rising into the home. Next, the team performed crawl space vent replacements, installing durable, weather-resistant vent covers to better seal the space while maintaining proper accessibility. These covers help prevent outside air, pests, and debris from entering, contributing to a more stable and energy-efficient environment. Finally, new fiberglass insulation was installed in the floor joist cavities to restore the thermal barrier between the crawl space and living area above. This helps keep the home warmer in winter, cooler in summer, and reduces energy costs.

Cumberland , In

August 14, 2002

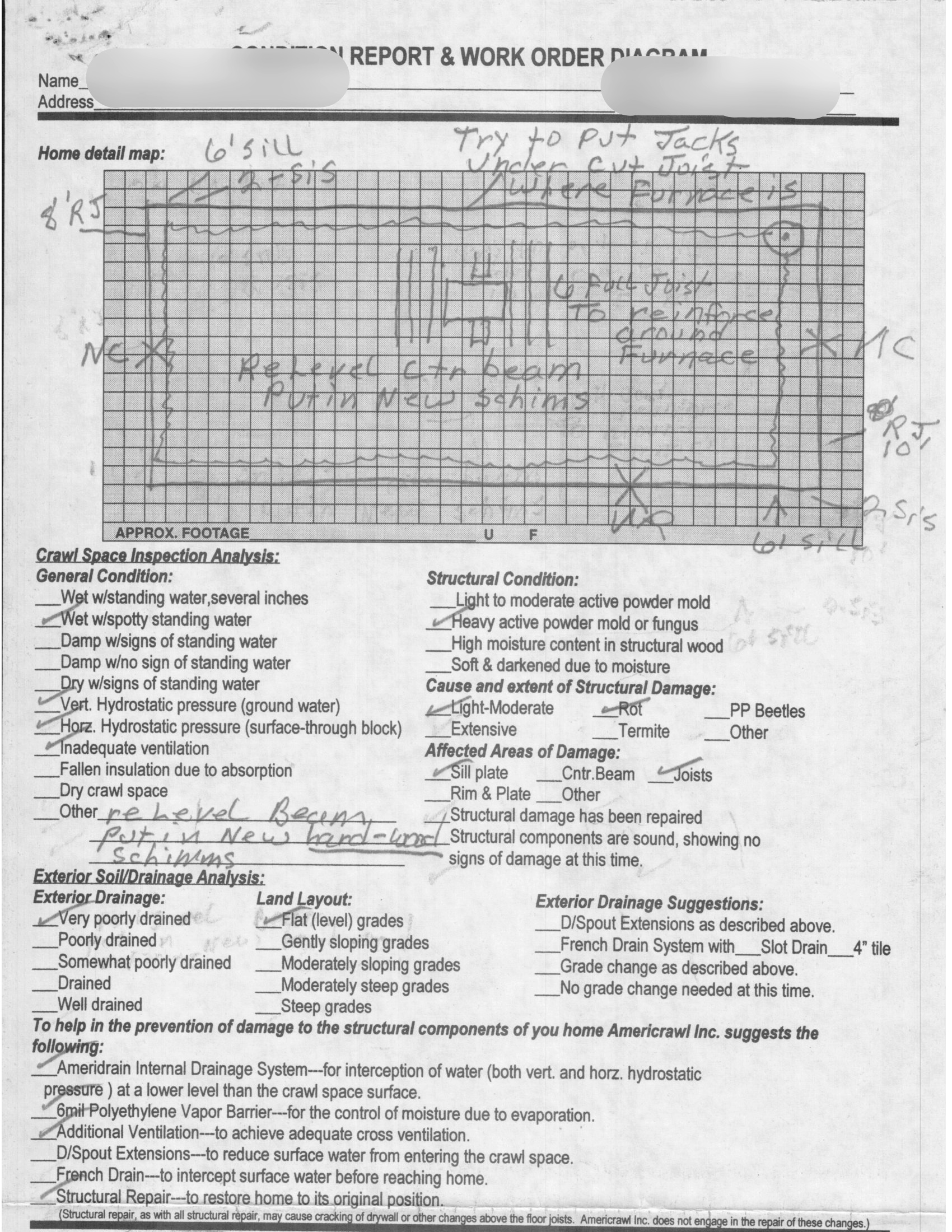

For this project, our crew completed a series of improvements to both the drainage and structural integrity of the crawlspace. We installed 135 feet of AmeriDrain Crawlspace Drainage System, designed to effectively capture and redirect groundwater away from the foundation, helping to keep the space dry and protected. To further support water management, we added an AmeriSump sump station, ensuring reliable removal of any collected water and reducing the risk of flooding or moisture buildup. Structural repairs were also a key part of this job. Our team re-leveled the center beam to restore proper support throughout the crawlspace and completed six floor joist repairs to strengthen the home’s framing system. In addition, we replaced eight feet of rim joist and plate to address areas weakened by moisture damage. Lastly, we installed a durable vapor barrier, providing a protective layer that helps control humidity, reduce mold growth, and create a cleaner and healthier crawlspace environment.

Whitestown, IN

June 24, 2002

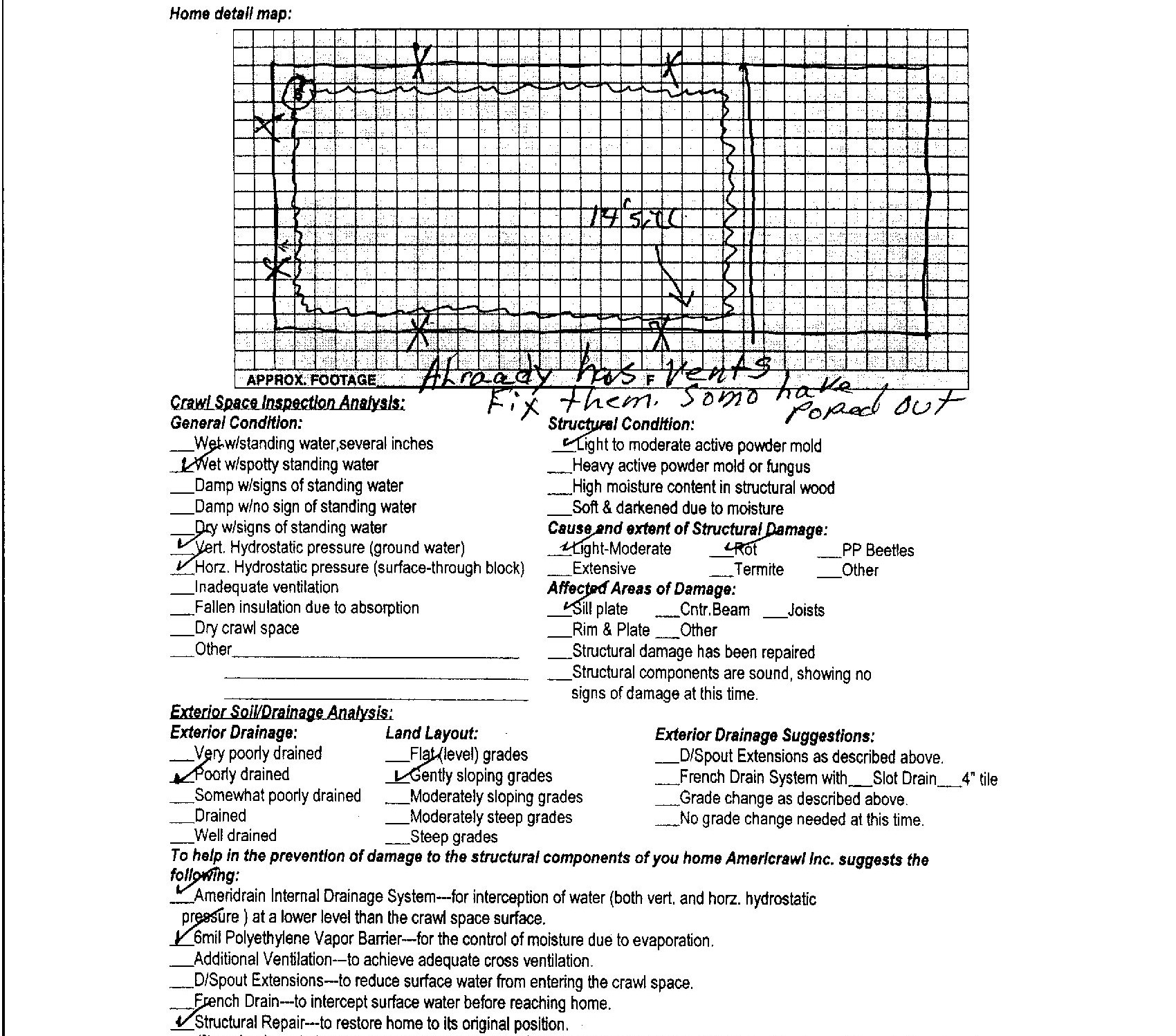

We began by installing a crawl space drainage system along the interior perimeter. This system efficiently collects groundwater and channels it to a designated discharge point, preventing standing water and reducing the risk of wood rot and mold. To protect the space from ground moisture, we installed a 6-mil vapor barrier across the crawl space floor. This barrier reduces humidity, helps control mold growth, and creates a cleaner, more stable environment beneath the home. Our Crew then replaced sections of the sill plate that had deteriorated from moisture, using pressure-treated lumber for long-lasting durability. In addition, several floor joists were repaired and sistered to restore structural support and eliminate sagging in the floors above.

Roachdale , In

January 29, 1999

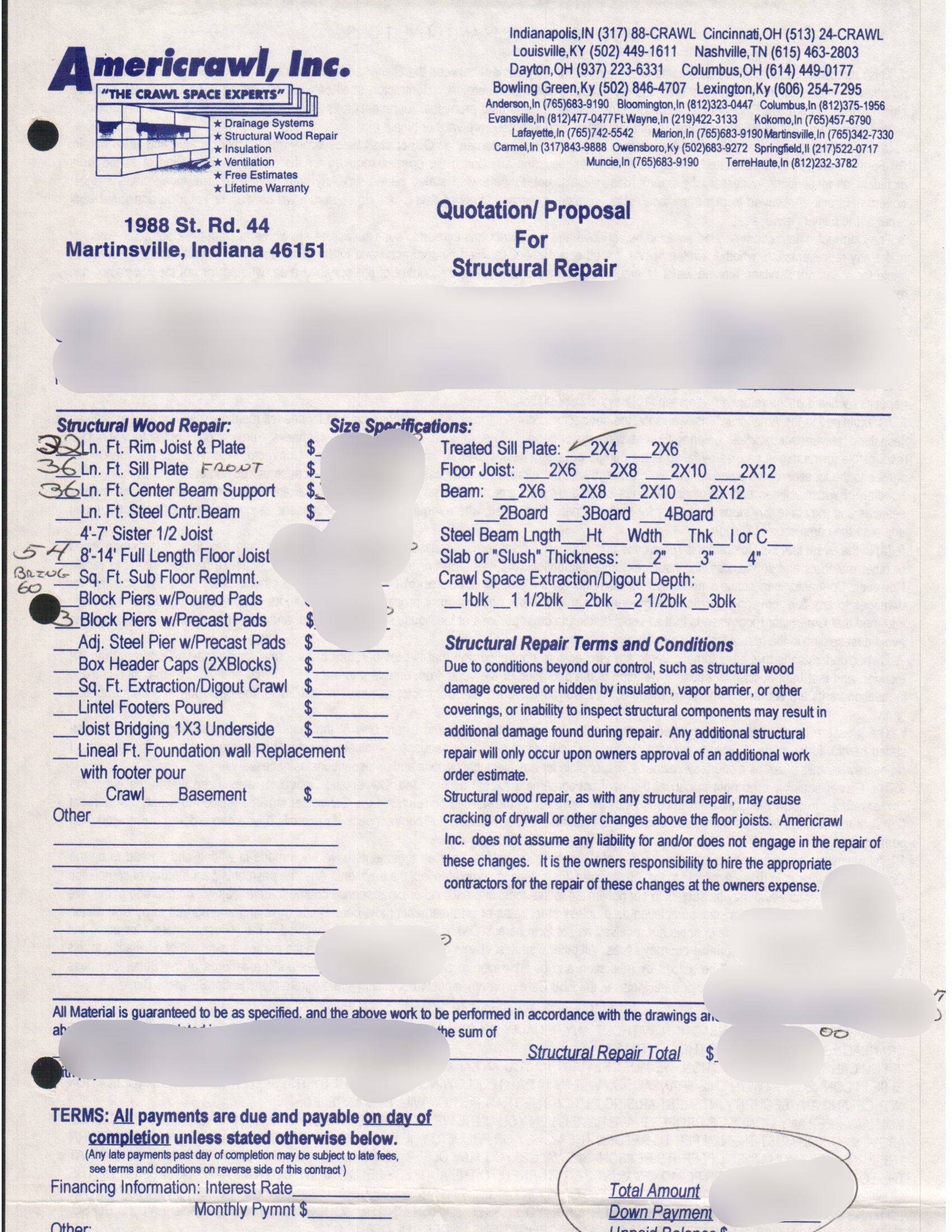

This project included extensive structural wood repair throughout the crawlspace. The crew installed 32 feet of new rim joist and plate, along with 36 feet of sill plate replacement to restore proper load-bearing support along the perimeter. In addition, 36 feet of center beam replacement was completed to stabilize the main structural span of the home. The repair scope also included the installation of 54 full-length floor joists to replace damaged or weakened framing members and provide complete structural reinforcement. Areas of damaged or deteriorated subfloor were removed and new subflooring was installed to restore stability above. To properly support the new center beam, the team installed three poured concrete pads, creating a solid resting base for long-term structural integrity.